-

- Index

Photo GalleryQuotation RequestContact usFrequently Asked QuestionsShippingTechnical Pages

-

Gabion

Australian manufactured weld mesh.

Weld Mesh AL-TEN 4mm- Gabion Kitsets 4mm (75 x 75 pitch)

- Gabion Kitsets 4mm (100 x 50 pitch)

- Gabion Panels 4mm (75 x 75 pitch)

- Gabion Panels 4mm (100 x 50 pitch)

Weld Mesh AL-TEN 5mm- Gabion Kitsets 5mm (75 x 75 pitch)

- Gabion Panels 5mm (75 x 75 pitch)

Al-Ten kitsets come complete with accessories.

Gabion Polymer Coated WovenTools & Accessories Gabion Weld Mesh

Gabion Weld MeshAustralian manufactured weld mesh with a 300gsm coating of 10% Aluminium and 90% Zinc.

Gabion Polymer Coated Woven

Gabion Polymer Coated WovenMaccaferri polymer coated gabion and accessories.

-

Textiles

Weed MattingGeotextile (nonwoven)Geotextile (woven)Accessories

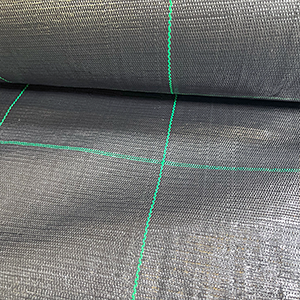

Weed Matting

Weed Matting110gsm premium weed matting, manufactured to the highest possible quality.

Geotextile (woven)

Geotextile (woven)Primary Applications: soil separation and reinforcement for paved or unpaved roads, access roads, farm gateways, forest roads.

Geotextile (nonwoven)

Geotextile (nonwoven)Primary Applications: drainage, soil separation for retaining walls, stabilisation and reinforcement for paved or unpaved roads, erosion control.

Accessories

AccessoriesGround staples (weed mat U pins in sharpened gal coated 4mm), butterfly Permaclips.

-

Root Barrier

Root BarrierBentonite Sodium Civil Engineering Grade

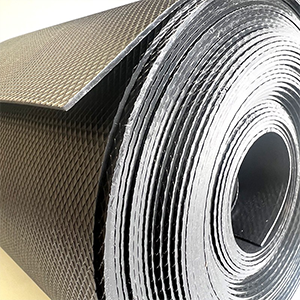

Root Barrier

Root BarrierRoot barrier is Australian manufactured to AST D1599/1505. Available in 1mm, 2mm and 3mm.

Bentonite Sodium Civil Engineering Grade

Bentonite Sodium Civil Engineering GradeCivil enginerring grade bentonite, used for a variety of applications including as a root barrier at the base of trenches, sealing earth dams, drilling.

-

Drainage & Pavers

Drainage & Pavers

Delta Geo 9mm Drainage Board

Delta Geo 9mm Drainage BoardDimpled sheeting with geotextile backing ideal for basement walls.

Hexcell drainage modules

Hexcell drainage modulesModular drainage manufactured in HDPE. 30mm thickness. Provides a non-clogging void between building structure for the efficient discharge of water.

Megaflo & Accessories

Megaflo & AccessoriesMegaflo drainage coil and accessories for 170mm and 300mm Megaflo.

Grass Pavers

Grass PaversGeohex soil erosion control and surface stabilisation paver. Made in Australia.

-

Other Products

Geomembrane TapesGeomembranesFasteners & ToolsAccessories

Geomembrane Tapes

Geomembrane TapesVulcanseal G-25 is a UV stabilised single sided adhesive tape designed for geomembrane joins and patches. Vulcanseal 609 is a double sided polyisobutylene tape.

Fasteners & Tools

Fasteners & ToolsFasteners and tools including hog rings, hog ringers, Nikolock, U Clips.

Accessories

AccessoriesGround Staple Pins for weed mat and geofab, butterfly clips for shadecloth